Construction begins on the world's largest RAS trout farming center

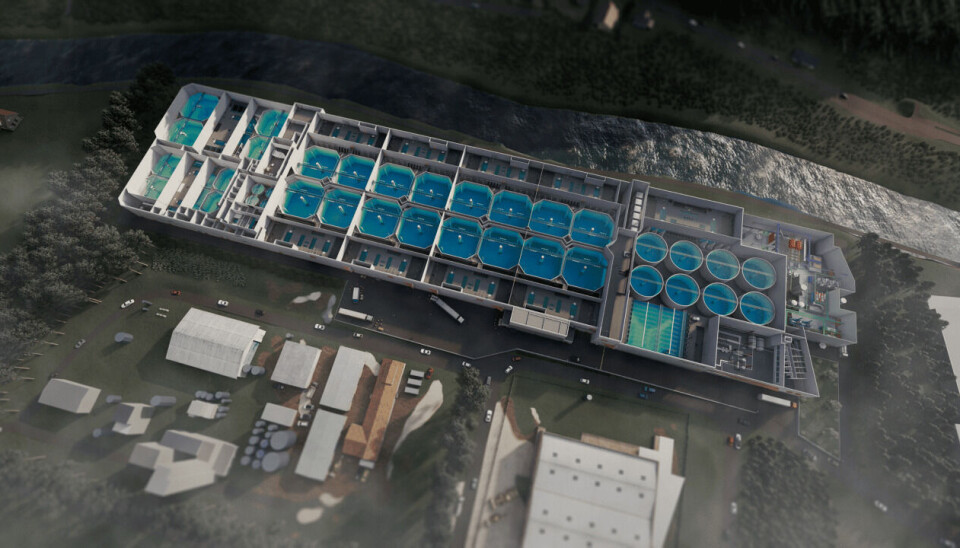

Norway: The facility will be 320 meters long and have a built area of about 27,000 m2 on two floors. Partial operations are expected to begin this year and stable operations in 2025.

On August 1, construction began on the world's largest RAS trout farming facility, led by Hima Seafood Rjukan, which will be located in Rjukan, Norway, and is expected to produce approximately 150 tons of trout per week, about 8,000 tons annually.

Hima Seafood Rjukan has secured financing from two infrastructure funds focused on sustainability managed by Foresight Group and P Capital Partners ("PCP"), a Swedish credit fund. The sustainability and ESG aspect of this project has been one of the main drivers for these funds to invest in Hima Rjukan. In addition to external capital, Hima's founders have made other significant investments in the facility. Together, the parties have committed $235 million.

The sustainable and reliable production of food in controlled environments is gaining importance due to global population growth and the limitation of natural resources. What makes the Rjukan project attractive is the high level of fish welfare that the facility will adhere to, which is reinforced by the strict standards in Norway that promote fish welfare. This combination has provided investors, especially Foresight Group, the peace of mind they were looking for to make their first investment in the aquaculture sector.

The investment will allow the construction of a facility that uses the latest proven technology, where fish will be incubated and grown up to a maximum size of 5 kg. The facility will also include a state-of-the-art water treatment system that will allow cleaning and recycling 99.3% of the wastewater for further use in order to reduce water demand. Additionally, an 11 km discharge pipeline for wastewater will be constructed, which will be financed by the municipality of Tinn and Hima Seafood Rjukan.

"Ensuring a constant and stable water temperature for our fish is fundamental to produce a first-class product. Superior product quality and environmental sustainability are not just slogans for us, they are part of Hima's DNA," commented Sten Falkum, CEO of Hima Seafood.

The facility will be 320 meters long and have a built area of about 27,000 m2 on two floors. Partial operations are expected to begin this year and stable operations are expected to start in 2025.

"We have chosen Rjukan for several reasons: its access to high-quality fresh water (important for taste), proximity to the market, access to specialized process knowledge, and access to affordable green energy, which further enhances the project's overall (sustainable/environmental) credentials," Falkum explained.

Attractive and Sustainable Proposal

"We are pleased to make our first investment in land-based aquaculture, contributing to the sustainable supply of trout to meet the growing demand from consumers. We believe this investment will bring environmental benefits to the food system and will offer a product that meets the needs of today's consumers," said Chris Tanner, partner at Foresight Group LLP.

"PCP has been actively financing the transition to sustainability in the economy for years. Land-based aquaculture will play a fundamental role in the sustainable production of proteins globally. Hima Seafood has put sustainability at the forefront and we are delighted to be their partner in financing this Nordic project," stated Daniel Sachs, CEO of P Capital Partners AB.

Focus

The Rjukan facility will use the modern RAS technology, designed by Eyvi and built by Total Betong. Eyvi has over 80 years of experience in the aquaculture industry among its specialists, having participated in the design and delivery of 16 smolt production facilities, including 58 RAS facilities. Total Betong is an established provider of engineering, procurement, and construction with experience in building several RAS smolt facilities in Norway.

Osland Stamfisk, a provider of eggs with decades of experience, will provide Hima with optimal genetics to produce premium quality trout. This genetics will be based on the Osland strain, which Osland Stamfisk has been researching and breeding since the 60s. The Osland strain provides unique genetics, very suitable for RAS production on land and is recognized as one of the trout specialists.

Villa Seafood, a Norwegian seafood distribution company with global presence, will be responsible for the processing, sale, and distribution of finished trout products. Villa Seafood is currently building a new processing and packaging plant in the Oslo area to accommodate the volumes from Hima Rjukan. In collaboration with Kind, a multi-award-winning international agency, a comprehensive sales and marketing strategy focused on high-end products for retail and businesses has been developed.

"We are looking forward to adding Hima trout to our range of high-end seafood products, as we consider it the perfect choice for our demanding customer base. With an increased focus on sustainability and transparency in food production, the Hima production model will fit well with current market trends and the demands of the modern consumer," highlighted Ove Thu, CEO of Villa Seafood Group.