Former Scotland land-based pioneer unveils plans for ex-Atlantic Sapphire Denmark site

Maiken Foods founder Arve Gravdal operated in hangar at Machrihanish

Arve Gravdal, a Norwegian land-based farming entrepreneur who once operated a salmon farm in an aircraft hangar at Machrihanish on the Kintyre peninsula in Scotland, is beginning a new venture in Denmark.

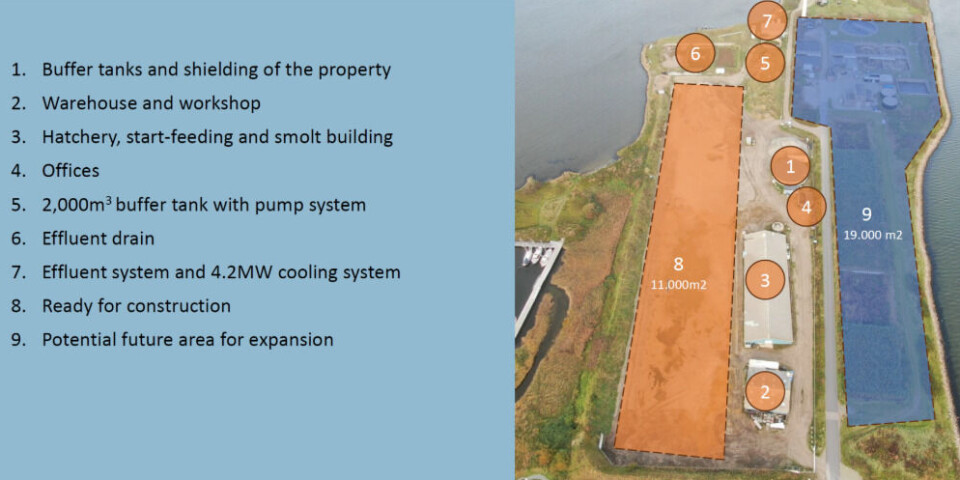

Gravdal’s company, Maiken Foods AS, has leased the former recirculating aquaculture system (RAS) salmon facility previously operated by Atlantic Sapphire Danmark AS at Hvine Sande.

Maiken Foods has also secured an option to purchase 100% of the shares in Atlantic Sapphire Danmark AS.

The RAS facility on Denmark’s west coast was damaged by a fire in September 2021 that led to the deaths of all the fish being grown there. Atlantic Sapphire, which was focused on its larger site in Florida, chose not to resume operations at Hvinde Sande and had the damaged areas cleared before putting the site up for sale.

“Functional features like smolt production, water intake, storage, buffer tanks, a cooling system, and effluent treatment remain,” said Atlantic Sapphire co-founder Thue Holm in July 2023. “The site is backed by a 6,400 amps power supply and all required permits. It has potential as a post-smolt site for Northern European salmon farmers or other fish farming projects.”

Stable growth

In a press release published on the Maiken Foods website, Arve Gravdal said the lease agreement marks the start of the company’s own project with proprietary technology.

“During the first half of the year, we will prove that we can achieve stable growth of large salmon all the way to market size. Our method combines the best features of traditional cage technology with the advantages of land-based production, while eliminating the biological and environmental challenges that characterise both solutions.”

The first and only cycle at Machrihanish ended prematurely amid reports of a die-off. Gravdal told Fish Farming Expert that the fish were harvested early because detergent had polluted the water supply, but that performance until that point had proved that the concept worked.

As had been planned at Machrihanish, where Gravdal had only one large tank, each production tank will be independent. Maiken says its Dynamic Water Treatment System (DWTS) allows continuous adjustments to various water treatment processes, which it says will enable it to achieve an optimal production water environment.

With Maiken’s system, juvenile salmon weighing 200-1200 grams will be stocked in the tanks and harvested months later. The entire process is fully automated.

Earlier cash flow

The company says it can construct individual fish tanks with short build times, allowing it to begin production in the first tank while the next tanks are still under construction. This approach generates early cash flow, significantly reduces project risk, and provides exceptional flexibility in scaling and progress.

“We have reduced investment costs by about two-thirds compared to traditional recirculation plants,” explained Gravdal. “This gives us the opportunity to reduce fish density accordingly, while maintaining sustainable economics. Another advantage is that the farming tanks are independent of each other, which prevents the spread of infection and allows for new, flexible farming strategies.”

When the first tank is commissioned in the spring, Maiken Foods plans to invite investors to a demonstration of the technology. At the same time, the company will solicit binding bids for tanks of various sizes. The goal is to document stable, high-quality production and demonstrate that large-scale land-based salmon farming is both possible and sustainable.

The company says its technology meets modern requirements for sustainability, fish welfare and environmental considerations – factors that both green investment funds and traditional funds now strongly emphasise.