Bank analyst backs hybrid flow-through systems to change fish farming

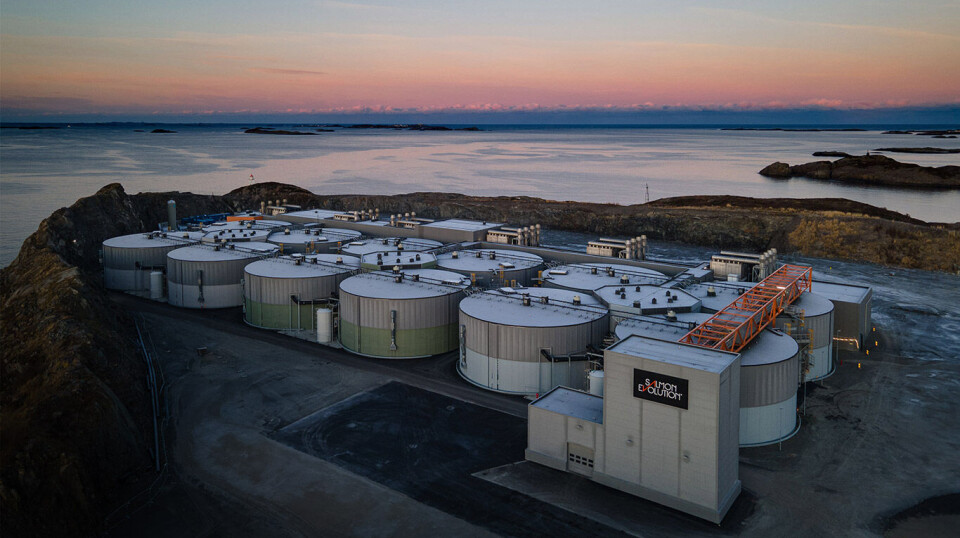

A leading analyst with major aquaculture lender Rabobank has backed land-based hybrid flow-through systems (HFS) to become a game changer for salmon farming.

Gorjan Nikolik, senior seafood analyst for RaboResearch Food & Agribusiness, says HFS can become a key part of the sector, enabling growth by producing harvest-size fish and large post-smolts for marine sites, while simultaneously improving biosecurity and reducing environmental impact.

“The limitation of the current, marine cage-based industry is the inability to sufficiently grow supply. Despite being highly technically advanced, Norwegian salmon farming experienced increasing levels of mortality in both 2023 and 2024,” notes Nikolik, who has produced a report on HFS for RaboResearch customers.

Lice, infections, and jellyfish

The cause was a combination of lice treatments, which have the side effect of reducing the protective layer on a salmon’s scales, and exposure to bacterial infections and jellyfish stings resulting from that eroded protective layer. HFS aquaculture is one of the alternatives that can change this situation materially. By moving farming into contained basins on the shore, it is possible to exclude most pathogens, such as lice, bacteria, algae, and jellyfish. This minimises the need for medication, resulting in faster growth rates and better feed-conversion ratios.

“Early data shows feed-conversion ratios of 1.1 on HFS farms compared to an industry average of 1.3. These results, combined with a survival rate of 97% compared to 83% for the net pen industry, suggest that biological performance on HFS farms is superior,” explains the analyst.

The higher biosecurity of HFS leads to a higher percentage of superior-grade fish compared to traditional farming methods, resulting in higher prices. Additionally, HFS farms have a lower environmental footprint, as they do not release pathogens into the surrounding waters and have minimal risk of fish escapes. “Nitrogen levels will be greatly reduced with HFS technology, as the key sources of nitrogen from traditional farms are collected at the bottom of the tank and not released with the water exiting the farm,” notes Nikolik.

Price offsets energy use

While HFS represent an improvement in biosecurity and sustainability due to their limited impact on the aquatic environment, they consume more energy than traditional net-pen farms. Between 1 and 8kWh of energy is needed to produce one kilogram of HFS salmon, depending on the systems used. In contrast, the marine stage of traditional salmon farming has negligible energy use.

“The bottom line is that the good price and the lower biological cost of production outweigh the higher energy cost and should lead to improved profitability,” states Nikolik. However, to make a real improvement in sustainability performance, HFS farms will need to be powered by sustainable sources of energy. “Fortunately, all the current projects we are aware of (in construction or planned) have renewable energy as a source.”

Billions needed

Nevertheless, substantial capital investment and supportive legislation are crucial for the widespread adoption of HFS technology. Current projects in Norway and Iceland are leading the way, but expansion into other regions like Chile, the United States, and Canada will require significant financial backing and regulatory support.

“Our estimates are that the projects currently operating and under construction will need between €2 billion and €3bn of capital between 2024 and 2030 for their existing plans,” notes Nikolik.

A much higher amount will be needed if the large number of conceptual and permitted projects are to become reality. HFS technology has the potential to transform the salmon farming industry, provided that the necessary capital and legislative frameworks are in place, concludes Nikolik.