Grow for it! Salmon farmer gets green light for sludge-to-fertiliser plan

Bakkafrost granted Scotland's first licence for a hatchery pyrolysis unit.

Salmon farmer Bakkafrost Scotland has been given the go-ahead for a cutting-edge treatment system which turns the sludge produced at its flagship Applecross hatchery and smolt facility into fertiliser.

The Scottish Environmental Protection Agency (SEPA) has granted the first Waste Management Licence in Scotland for a hatchery pyrolysis unit and Bakkafrost Scotland will build the new treatment system to create biochar from sludge produced at the recirculating aquaculture system (RAS) facility.

The process dries the sludge and turns it into inert biochar which is known as a fertiliser and soil improver, refining the structure and water retention in soils. This process also ‘locks away’ carbon permanently.

Heated to 700°C

In the first stage, hatchery sludge, which is approximately 97% water, is treated by going through a filter belt. The water content is reduced to about 80% and the dry matter content is increased to about 20%.

The next stage requires the licence as it incorporates a pyrolysis unit which dries sludge at about 300°C, generating sludge pellets. These are then heated to 700°C without the presence of oxygen during a pyrolysis process. Heat is effectively absorbed and repurposed inside the system, increasing total energy efficiency. The end product is a biochar which is a material with a high stable carbon content.

Bakkafrost Scotland managing director Ian Laister said: “In a RAS facility, substantial quantities of unused ‘waste’ materials are generated, which must be separated from the water circulating back to the fish.

“Traditionally, that material has been considered waste, but technological advancements have opened the door to a more sustainable management process and that must be good news for helping protect our environment.

“All of this is very much in line with Bakkafrost Scotland’s sustainability goals and supports building a circular economy from farm to fork.”

Sustainable power

Bakkafrost Scotland’s ambition for its RAS facilities is to reduce waste by 90%, to use 100% sustainable power and to reduce the water used in the process by 90%. Hydro, solar, recycled material, and heat recovery systems will be used to reduce impact on the environment.

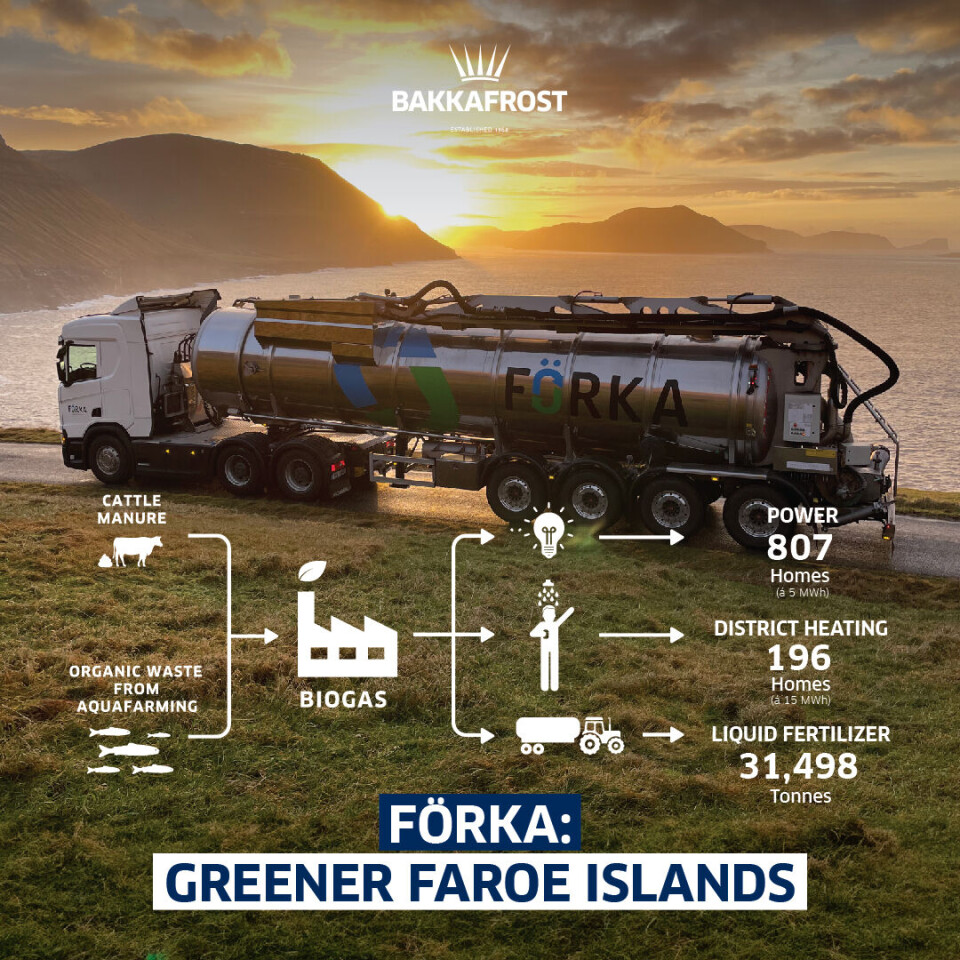

In its home country, Faroese parent company Bakkafrost P/F combines waste from its hatcheries with cow manure at its Förka biogas plant. The gas is used to generate heat and power for homes. The waste is then used for liquid fertiliser.

In 2023, the facility produced 31,498 tonnes of fertiliser, which it said significantly contributed to the agricultural sector in the Faroe Islands. Additionally, Förka generated 4,036 MWh of electricity for the Faroese grid and provided 2,939 MWh of district heating. The electricity was calculated to provide the needs of 807 homes and the district heating kept 196 homes warm.

Learn more about pyrolysis from this article that appeared in Fish Farming Expert last year.