Andfjord Salmon's toughest task '98% complete'

The land-based fish farmer expects to have seawater flowing in its tunnels in Q2

The technically demanding construction of a waterway system for land-based fish farmer Andfjord Salmon’s near-24,000-tonne flow-through facility is 98% complete, the Norwegian company said in a market update today.

The tunnel system beneath the pits that will contain 12 fish pools is finished, with only 6-7 metres remaining of the outlet waterway and approximately 70 metres left to complete the inlet waterway.

Andfjord Salmon said it plans to execute the final breakthrough from the inlet/outlet tunnel to the sea in the second quarter of this year.

“Filling the tunnels with water for the first time will mark a significant milestone in preparing the facility for fish farming operations. This step brings us closer to realising our vision, and we look forward to achieving this important breakthrough,” said chief executive Martin Rasmussen.

Strong momentum

Andfjord Salmon is completing four new pools and developing a new harbour area in the initial build-out phase at Kvalnes on the island of Andøya. It said today that the pool construction is advancing as planned and has now reached 65% completion. Installation of the pools’ technical infrastructure is currently at 25% completion.

Development of the harbour area is 71% complete. A temporary breakwater has been constructed to shield ongoing construction work from the sea. Once the harbour and port infrastructure are fully completed, the outer section of the breakwater will be removed, allowing vessels to enter and operate within the protected harbour.

"Construction activity is maintaining strong momentum, and we are in parallel beginning preparations for infrastructure testing,” said Rasmussen.

Gentler transfers

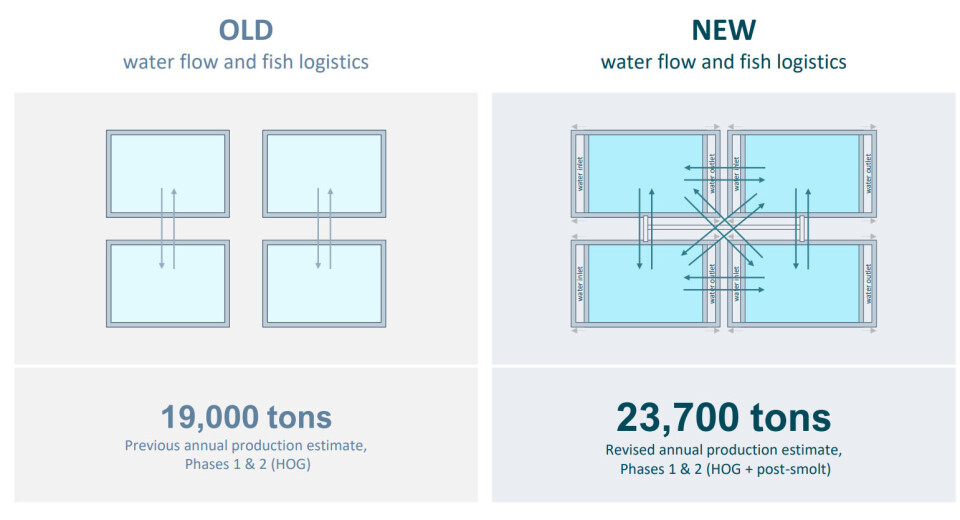

Andfjord has previously announced an optimised build-out plan to boost production by 20% by using a more efficient and gentle fish logistics system and reinforced concrete walls to enhance water flow.

Originally, Andfjord had planned for splitting between pools to utilize piping going over the walls, one time per life cycle. Now, with a new design developed together with fish handling experts and core partner Cflow, the company will move fish using a network of piping below the ground, a method that imposes less stress on the fish.

The revised logistics system also enables more flexibility in splittings, meaning that pools will have a higher average number of fish across all pools, improving utilisation of capacity.

Andfjord said the method for moving fish entails having a lower water level in the ‘receiving’ pool versus the ‘sending’ pool, resulting in a natural flow of water and fish between pools. This added water pressure means that walls need reinforcing.

Reduced CAPEX per kilo

The expanded production will result in an expanded production capacity from 8,000 tonnes to up to 11,000 tonnes (head on gutted salmon plus post-smolts for on-selling) for the current build-out phase (Phase 1) at Kvalnes. The total production volume under Andfjord Salmon’s existing licence at Kvalnes is expected to increase from 19,000 tonnes to 23,700 tonnes. The company says the increase in tonnage will reduce capital expenditure (CAPEX) per kilo from NOK 114 to NOK 105.

Andfjord Salmon is now planning for immediate start of Phase 2a construction which will allow the company to benefit from construction synergies due to the continuous process across phases, e.g., through the retention of personnel and use of equipment already on-site, optimising the resource usage and accelerating execution time.